With the vigorous development of consumer electronics and automotive electronics, 5G has also ushered in a commercial boom. With the upgrading of electronic technology and the increasing complexity of electronic products, coupled with the increasingly harsh use environment of electronic products, it is difficult for the system to ensure a certain period of time. The ability or possibility to perform specified functions without failure within certain conditions. Therefore, in order to confirm that electronic products can work normally in these environments, national standards and industrial standards require simulation of some test items.

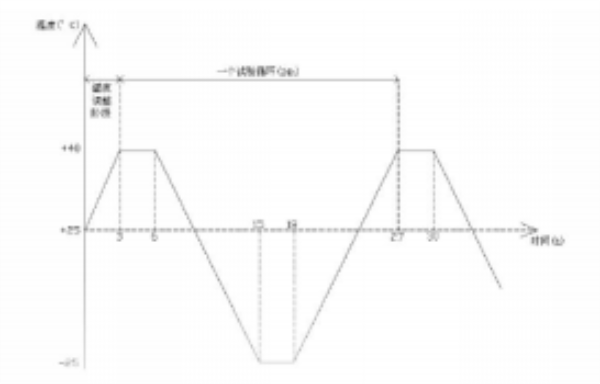

Such as high and low temperature cycle test

The high and low temperature cycle test means that after the set temperature is kept from -50°C for 4 hours, the temperature is raised to +90°C, and then the temperature is kept at +90°C for 4 hours, and the temperature is lowered to -50°C, followed by N cycles.

The industrial temperature standard is -40℃ ~ +85℃, because the temperature cycle test chamber usually has a temperature difference. In order to ensure that the client will not cause inconsistent test results due to temperature deviation, it is recommended to use the standard for internal testing.

Bad to test.

Test process:

1. When the sample is powered off, first drop the temperature to -50°C and keep it for 4 hours; do not perform low temperature testing while the sample is powered on, it is very important, because the chip itself will be produced when the sample is powered on.

Therefore, it is usually easier to pass the low temperature test when it is energized. It must be "frozen" first, and then energized for the test.

2. Turn on the machine and perform performance test on the sample to compare whether the performance is normal compared with normal temperature.

3. Carry out an aging test to observe whether there are data comparison errors.

Reference standard:

GB/T2423.1-2008 Test A: Low temperature test method

GB/T2423.2-2008 Test B: High temperature test method

GB/T2423.22-2002 Test N: Temperature change test method, etc.

In addition to the high and low temperature cycle test, the reliability test of electronic products may also be the temperature and humidity test (Temperature And Humidity test), the alternating damp heat test (Damp Heat, Cyclic test)

(Low Temperature Storage test), High Temperature Storage test, Thermal shock test, Salt Spray Te

Random/sine (Vibration test), box free drop test (Drop test), steam aging test (Steam Aging test), IP level protection test (IP Test), LED light decay life test and certification

Measuring Lumen Maintenance of LED Light Sources), etc., according to the manufacturer's product testing requirements.

The temperature cycle test box, constant temperature and humidity test box, thermal shock test box, three comprehensive test box, salt spray test box, etc. developed and produced by Ruikai Instruments provide solutions for the reliability test of electronic products.

The temperature, humidity, sea water, salt spray, impact, vibration, cosmic particles, various radiation, etc. in the environment can be used to determine the applicable reliability, failure rate, and mean time between failures of the product in advance.

Post time: Aug-28-2023