Products

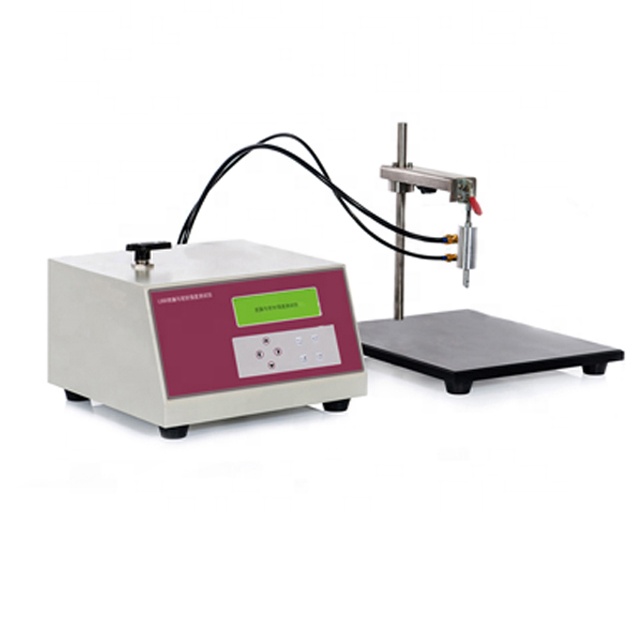

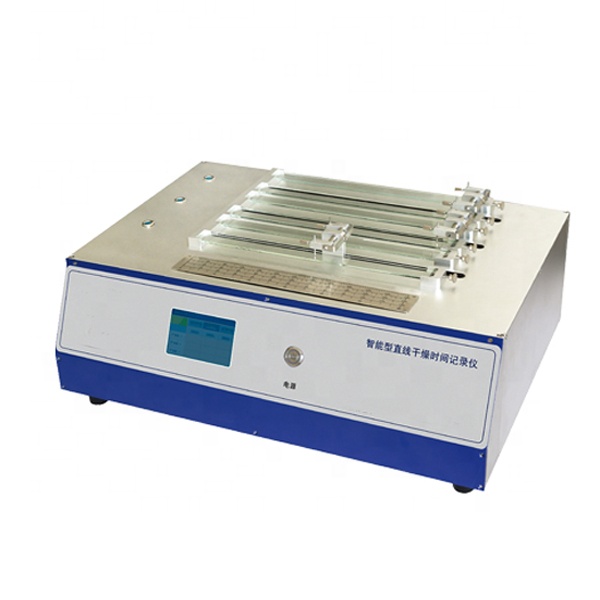

UP-6036 Package Leak and Seal Strength Detector

Character

♦ Based on the positive pressure method and controlled by micro-computer, with LCD, menu interface and PVC operation panel.

♦ Dual test methods of restraint distension and unrestraint distension for customer’s free choice.

♦ Different test modes of burst, creep, and creep to failure to meet different test requirements.

♦ Optional test range, “one key operation” and other intelligent designs support combinations of non-standard test conditions.

♦ Professional software provides automatic statistics of test data.

♦ Equipped with micro-printer and standard RS232 port for convenient PC connection and data transfer.

Standards:

ISO 11607-1,ISO 11607-2,GB/T 10440,GB 18454,GB 19741,GB 17447,ASTM F1140,ASTM F2054,

GB/T 17876,GB/T 10004,BB/T 0025,QB/T1871,YBB 00252005,YBB 00162002

| Basic Applications

|

Plastic Composite Bags Test the compression resistance of various plastic films, aluminum films, paper plastic composite films, aluminum plastic composite films and other packaging bags |

| Flexible Tubes Including various flexible tubes used in daily chemical products and other industries, e.g. flexible tubes of toothpaste, face cream, cosmetics, pharmaceutics and food |

|

| Creep Test Including various packaging bags and boxes |

|

| Creep to Failure Test Including various packaging bags and boxes |

Applications Specifications

| Extended Applications | Burst Test Of Blister Packs Including various blister packs |

||||||||||||||||

| Aerosol Valves Test seal performance of various aerosol valves, e.g. vales of pesticide, hair spray, auto spray paint and medical spray packages |

|||||||||||||||||

| Three-Sided Sealing Materials Test withstand pressurization stress of packaging bags with three-sided seal and one-sided open |

|||||||||||||||||

| High Pressure Test The maximum test pressure could reach 1.6MPa |

|||||||||||||||||

| Pilfer-proof Closures Test seal performance of various pilfer-proof closures, e.g. closures used in packages of Coke, mineral water, beverage, edible oil, sauce (soy, vinegar and cooking wine), three-piece cans (beer and beverage), and paper cans (cylinder shape for potato chips ) |

|

Test Range

|

0-250KPa; 0-36.3 psi(standard) |

|

0-400KPa; 0-58.0 psi (optional) |

|

|

0~600 KPa; 0~87.0 psi (optional) |

|

|

0~1.6 MPa; 0~232.1 psi (optional) |

|

|

Gas Supply Pressure |

0.4 MPa~0.9 MPa (outside of supply scope) |

|

Port Size |

Diameter 8mm PU Tubing |

|

Instrument Dimension |

300 mm (L) x 310 mm (W) x 180 mm (H) |

|

Pedestal Size |

305 mm(L) x 356 mm(W) x 325 mm(H) |

|

Power Supply |

AC 220V 50Hz |

|

Net Weight |

23 kg |

Our service:

During the whole business process, we offer Consultative Selling service.

FAQ:

Moreover, If your machine doesn’t work, you can send us an e-mail or call us we will try our best to find the problem through our conversation or by video chat if necessary. Once we have confirmed the problem, the solution will be offered within 24 to 48 hours.

Products categories

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur