Products

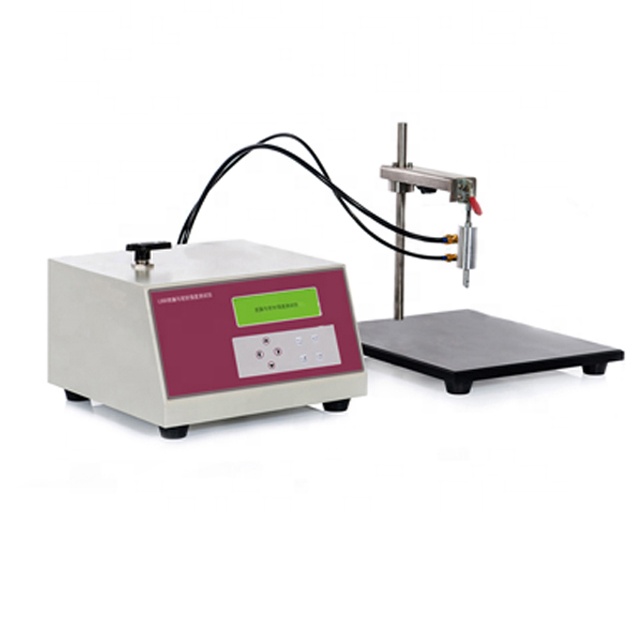

UP-6036 Package Leak and Seal Strength Detector

Character

♦ Based on the positive pressure method and controlled by micro-computer, with LCD, menu interface and PVC operation panel.

♦ Dual test methods of restraint distension and unrestraint distension for customer’s free choice.

♦ Different test modes of burst, creep, and creep to failure to meet different test requirements.

♦ Optional test range, “one key operation” and other intelligent designs support combinations of non-standard test conditions.

♦ Professional software provides automatic statistics of test data.

♦ Equipped with micro-printer and standard RS232 port for convenient PC connection and data transfer.

Standards:

ISO 11607-1,ISO 11607-2,GB/T 10440,GB 18454,GB 19741,GB 17447,ASTM F1140,ASTM F2054,

GB/T 17876,GB/T 10004,BB/T 0025,QB/T1871,YBB 00252005,YBB 00162002

| Basic Applications

|

Plastic Composite Bags Test the compression resistance of various plastic films, aluminum films, paper plastic composite films, aluminum plastic composite films and other packaging bags |

| Flexible Tubes Including various flexible tubes used in daily chemical products and other industries, e.g. flexible tubes of toothpaste, face cream, cosmetics, pharmaceutics and food |

|

| Creep Test Including various packaging bags and boxes |

|

| Creep to Failure Test Including various packaging bags and boxes |

Applications Specifications

| Extended Applications | Burst Test Of Blister Packs Including various blister packs |

||||||||||||||||

| Aerosol Valves Test seal performance of various aerosol valves, e.g. vales of pesticide, hair spray, auto spray paint and medical spray packages |

|||||||||||||||||

| Three-Sided Sealing Materials Test withstand pressurization stress of packaging bags with three-sided seal and one-sided open |

|||||||||||||||||

| High Pressure Test The maximum test pressure could reach 1.6MPa |

|||||||||||||||||

| Pilfer-proof Closures Test seal performance of various pilfer-proof closures, e.g. closures used in packages of Coke, mineral water, beverage, edible oil, sauce (soy, vinegar and cooking wine), three-piece cans (beer and beverage), and paper cans (cylinder shape for potato chips ) |

|

Test Range

|

0-250KPa; 0-36.3 psi(standard) |

|

0-400KPa; 0-58.0 psi (optional) |

|

|

0~600 KPa; 0~87.0 psi (optional) |

|

|

0~1.6 MPa; 0~232.1 psi (optional) |

|

|

Gas Supply Pressure |

0.4 MPa~0.9 MPa (outside of supply scope) |

|

Port Size |

Diameter 8mm PU Tubing |

|

Instrument Dimension |

300 mm (L) x 310 mm (W) x 180 mm (H) |

|

Pedestal Size |

305 mm(L) x 356 mm(W) x 325 mm(H) |

|

Power Supply |

AC 220V 50Hz |

|

Net Weight |

23 kg |

Products categories

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur