Products

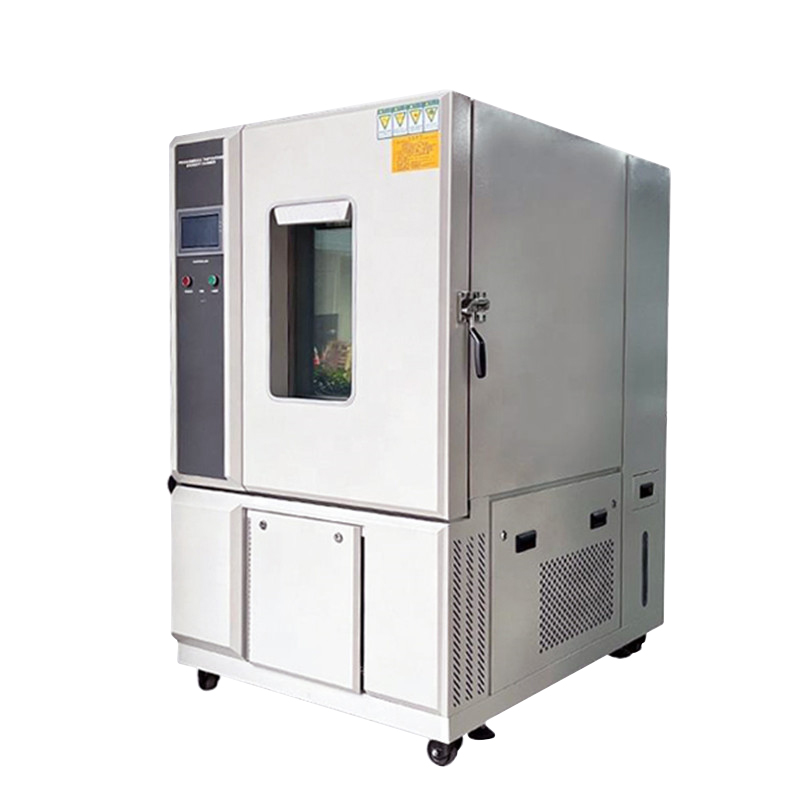

UP-6118 Thermal Shock Test Chamber

Based on the standard

IEC68-2-14(test method)

GB/T 2424.13-2002(test method change of temperature test guideline)

GB/T 2423.22-2002 (temperature change)

QC/T17-92 (auto parts weathering test general rules)

EIA 364-32{thermal shock (temperature cycle) test program electric connector and socket environment impact assessment}

USES

Cold and hot impact machine can be used to test material structure or composite material, in an instant by extremely high temperature and extremely low temperature continuous environment can endure degree, in order to in the shortest time test commits any heat bilges cold shrink caused by the chemical changes or physical damage. Applicable objects including LED,metal, plastic, rubber, electronics, pv, solar... And other materials, the products can be used as a basis of improving or reference.

Characteristic introduction

★ high temperature groove, low temperature groove, test grove is static.

★ Shock way uses wind path changing methods, let high temperature and low temperature leading to test area, and reach the high-low temperature shock test goal.

★Can set rotation times and defrost times.

★ Use touching colourful liquid controller, easy to operate, stable.

★ Temperature accuracy is high, use PID calculating methods.

★Choose start-move place, high temperature and low temperature is rotation.

★ Showing test curve when operation.

★Fluctuation two box structure conversion speed, recovery time short.

★Strong into refrigeration import compressor, cooling speed.

★Complete and reliable safety device.

★High reliability design, suitable for 24 hours of continuous test.

Technical parameters

|

Size(mm) |

600*850*800 |

|

Temp range |

High greenhouse: cold ~ + 150 ℃ low greenhouse: cold ~ - 50 ℃ |

|

Temp Evwnness |

±2℃ |

|

Temp conversion time |

10S |

|

Temp recovery time |

3min |

|

Material |

Shell: SUS304 # stainless steel plate Liner: SUS304 # stainless steel plate |

|

Refrigeration system |

Dual reciprocating compressors refrigeration(water-cooled), imports France Taikang compressor group,environmentally friendly refrigerant |

|

Control system |

Korea imported programmable temperature controller |

|

Temp sensor |

PT 100 *3 |

|

Setting range |

TEMPERATURE : -70.00+200.00℃ |

|

Resolution |

TEMPERATURE : 0.01℃ / TIME : 1 MIN |

|

Output type |

PID + PWM + SSR Control mode |

|

Simulation load (IC) |

4.5kg |

|

Cooling system |

Water cooled |

|

Meet the standard |

Products to satisfy GB, GJB, IEC, MIL, corresponding test standard test method |

|

Power |

AC380V/50HZThree-phase four-wire AC power |

|

Expansion characteristics |

Diffuser and return air palate know device detector control/CM BUS (RS - 485) remote monitoring management system/Ln2 liquid nitrogen quick cooling control device |