Products

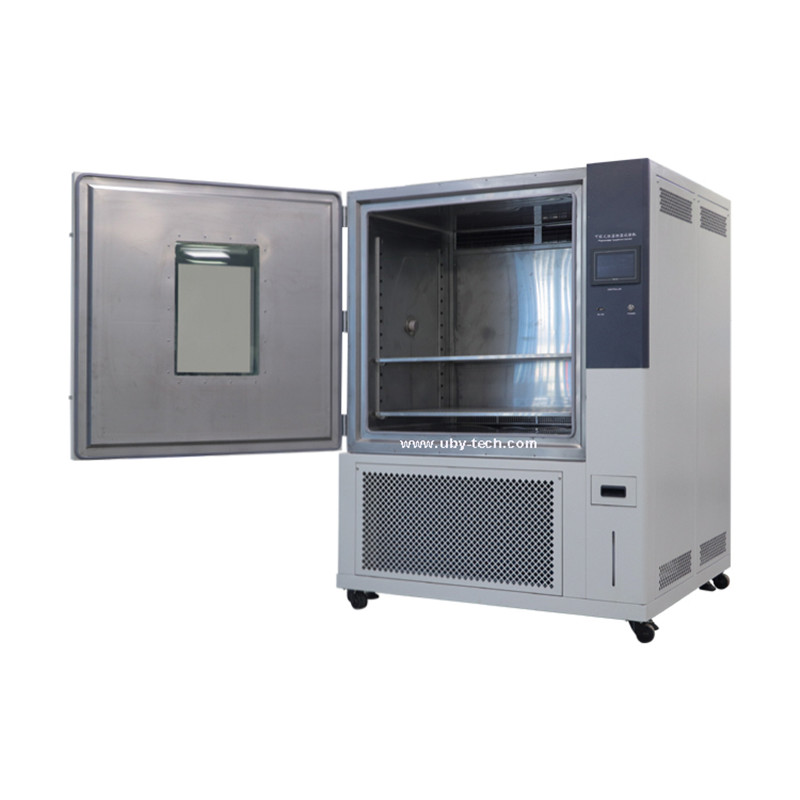

UP-6119 Ashing Muffle Furnace

Detailed technical parameters

|

Power |

2.5KW |

2.5KW |

4KW |

5KW |

9KW |

16KW |

18 KW |

|

|

Chamber size (DXWXH) |

200X150 X150 |

300X200 X120mm |

300X200 X200mm |

300X250 X250mm |

400X300 X300mm |

500X400 X400mm |

500X500 X500mm |

|

| Dimension(WXDXH) |

410*560 *660 |

466X616 X820 |

466X616 X820 |

536X626 X890 |

586X726 X940 |

766X887 X1130 |

840X860 X1200 |

|

|

Number of heating surface |

4 surface heating |

|||||||

|

Supply voltage |

220V |

220V |

220V |

380V |

380V |

380V |

||

|

Phase |

single phase |

single phase |

single phase |

three phase |

three phase |

three phase |

||

|

Heating element |

Imported resistance wire (Kan-thal A1, Sweden) |

|||||||

|

Control mode |

UAV program temperature control instrument (standard)1, 30-stage program temperature control intelligent PID adjustment.

2. With over-temperature protection, the electric furnace heating circuit is automatically cut off when the temperature is over-temperature or broken, (when the electric furnace temperature exceeds 1200 degrees or the thermocouple is blown, the AC relay on the main circuit will be automatically disconnected, the main circuit is broken. On, the ON light on the panel is off, the OFF light is on, and the limited protection electric furnace). 3, with 485 communication interface (standard when purchasing software) 4, with power-off protection function, that is, when the power is turned on after the power is turned off, the program does not start from the starting temperature, but the furnace temperature rises from the time of power failure. 5, the meter has the function of temperature self-tuning |

|||||||

| Furnacematerial | 1. High-quality high-purity alumina polycrystalline fiber curing furnace formed by vacuum suction filtration.2. Formed by Japanese technology.

3. The spacing and pitch of the resistance wires in the furnace are all arranged according to the best thermal technology in Japan, and the temperature field is simulated by the thermal software. 4, using 4 sides heating (left and right, four sides), the temperature field is more balanced |

|||||||

|

Control accuracy |

+/- 1 ℃ |

|||||||

|

Maximum temperature |

1200 ℃ |

|||||||

|

Rated temperature |

1150 ℃ |

|||||||

| · Thermocouple Type |

K Type |

|||||||

|

Trigger |

Phase-shifted trigger | |||||||

|

Maximum heating rate |

≤30℃/ Min |

|||||||

|

Recommended heating rate |

≤15℃/ Min |

|||||||

|

Safety protection system |

The furnace is equipped with safety and air switch when the current exceeds the rated current of the open air, the open air will automatically jump, effectively protecting the furnace |

|||||||

|

Door opening protection system |

The furnace is equipped with travel switch when the furnace door is opened, the main electric furnace will automatically power off |

|||||||

|

Silicon controlled |

· SEMIKRON 106/16E | |||||||

|

Ambient surface temperature |

≤35℃ |

|||||||

|

Warranty period |

One year warranty, lifetime technical support Special note, parts such as heating elements, sample files, etc. are not covered by the warranty. Damage caused by the use of corrosive gases is not covered by the warranty |

|||||||

| Notes | 1. For safety, please put the furnace in a ventilated place.2. In order to improve the service life of the furnace, we recommend that the heating rate not exceed 10 °C / min. The cooling rate does not exceed 5 ° C / min.

3, the furnace has no vacuum sealing, prohibiting the introduction of toxic or explosive gases 4. It is forbidden to place the material directly on the bottom of the furnace floor. Please place the material in the special concrete. 5, when heating, do not touch the heating element and thermocouple 6. When not in use for a long time, please use the oven again. |

|||||||