Products

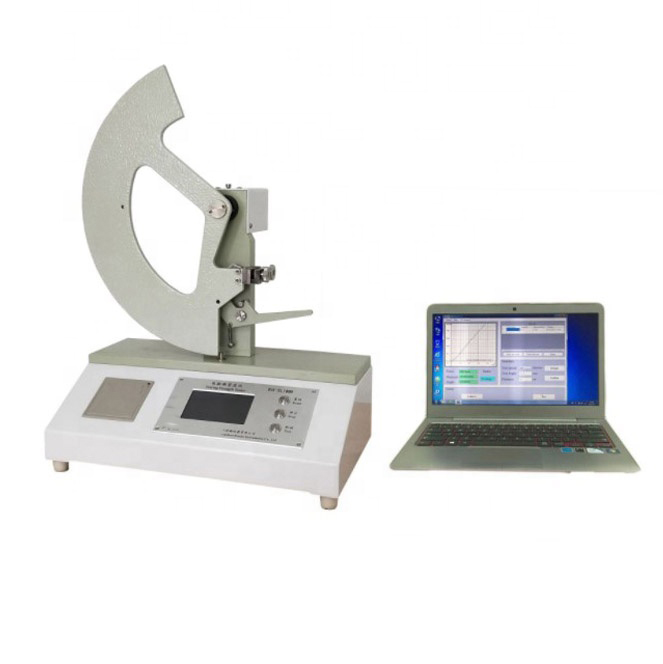

UP-6024 Automatic drawing ring method adhesion tester

Automatic drawing ring method adhesion tester

Using the ring method to evaluate the adhesion of the film and the substrate is one of the most traditional methods in China.This method uses a specially designed instrument to continuously draw many circles of the same diameter on the coating to be tested, these circles overlap each other at a certain distance, and then divide them into seven parts according to the area size of the intersecting part of the circle.When assessing, check the integrity of each part of the film, to a part of the area of more than 70% of the film intact to assess the corresponding grade It is the latest domestic automatic ring method adhesion tester, it meets the GB/T 1720 standard requirements, compared with the traditional domestic other machines, has the following characteristics:

All aluminum oxide body, high-grade, beautiful, light

1. The special indicator light can automatically judge whether the needle has cut the coating to the substrate, with the characteristics of accurate operation, convenient and so on Special precision machining needle, to ensure that different needle with good consistency Electric complete circle, uniform speed, constant strength, test results with high reproducibility and comparability.

2. Sliding platform is convenient for multiple tests at different positions on the same test board Rotary arm design, very convenient to change the needle and test plate.

3. Double nuts are used to adjust the clearance of the screw, which makes the platform run more smoothly, reduce the error caused by the clearance of threads and make the data more accurate The working platform adopts double guide limit, which is more stable than single guide.You can return to the starting point with one key after completing the single test

4. Special tool for drawing needle is more convenient and quick to assemble and disassemble Precision machining thread control ring diameter, test results more accurate.

5. Precise positioning of the starting point and end point of the working platform, strictly ensure that each test can meet the standard travel.

6. Multistage weight combination to get the most suitable weight load.

7. The weight plate is independently rotating design, which reduces the influence of its inertia on the test load when running.

Main technical parameters

| Turning radius | R=5.25mm |

| Guoquan length | 80mm |

| No-load pressure | 200g |

| Farmar weight | 100g,200g,500g |

| Scriber | The hardness of HRC 45 ~ 50 alloy,

Tip radius (0.05±0.01) mm |

| Scriber speed | About 90 RPM |

| Substrate requirement | 120 x 50 x 0.2 0.3 mm tinplate |