Products

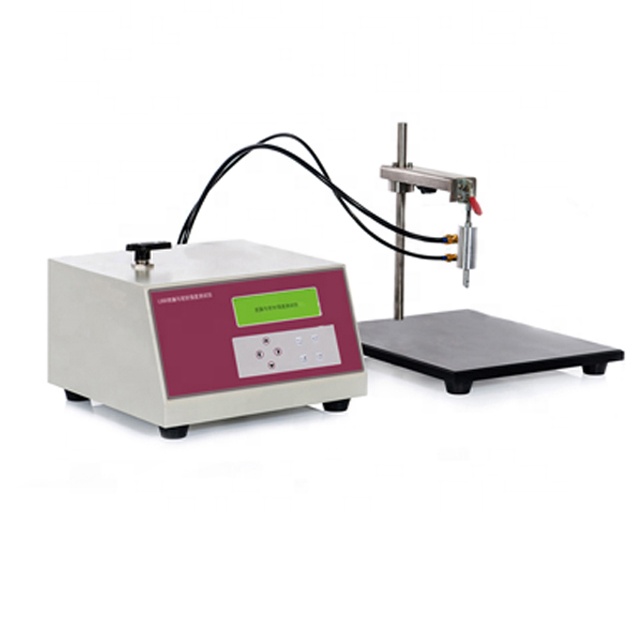

UP-6012 Minimum Film Forming Temperature Tester (MFFT Tester)

Tester Principle

Set a cooling source and a heating source on a suitable metal board and keepthem at a constant temperature to setting point. Different temperature grads would appear on this board because of metal heat conduction. Paint uniform thickness sample on this temperature grads board, the water of sample will be evaporated under heating of different temperature and sample will form film. The form film performance is different under different temperature. Find the boundary and then its corresponding temperature is MFT temperature of this sample.

Minimum Film Forming Temperature Tester(MFTT)is the newest high-precision product which has been developed. We use platinum resistance imported from Germany as temperature sensor, and use LU-906M intelligent temperature controller which combine fuzzy control theory with PID control , ensure it shows an error less than 0.5%±1 bit. In order to reduce size, we use special size grad board at all costs. Furthermore, there is water-break protection system for any water break, the machine will turn off automatically once there is water-break. For saving water consumption, we let tester screen show cooling water temperature (on the 15th and 16th point of inspection recorder), decrease the water consumption

as far as possible(by hand) according to different settings. In order to let operator judge MFT point successfully, we design clear and high graduated scale in the front of the working table.

It is accordance with ISO 2115, ASTM D2354 standard, and can test minimum film temperature of emulsion polymer easily and accurately.

Advantages

Wider working table, can test 6 groups sample at the same time.

Space saving desktop design.

Advanced design for grad board decreases the machine size.

Surface temperature is calibrated precisely, ensuring a accurate and reliable data with temperature scale.

Intelligent temperature controller, ensures error is less than0.5%±1 bit.

Cooled by semiconductor and big power switching voltage decreases noise from cooling system considerably

Main Technical Parameters

| Working temperature of grad board | -7℃~+70℃ |

| Number of inspection points of grad board | 13 pcs |

| Interval distance of grad | 20mm |

| Test channels | 6 pcs, length is 240mm, width is 22mm and depth is 0.25mm |

| Showing value of inspection recorder | 16 points,from No.1 ~ No.13 is working temperature grade, No.14 is environment temperature, No.15 and No.16 are cooling water temperature for inlet and outlet |

| Power | 220V/50Hz AC wide voltage(three-phase supply with good earth) |

| Cooling water | Normal water supply |

| Size | 520mm(L)×520mm(W)× 370mm(H) |

| Weight | 31Kg |

Our service:

During the whole business process, we offer Consultative Selling service.

FAQ:

Moreover, If your machine doesn’t work, you can send us an e-mail or call us we will try our best to find the problem through our conversation or by video chat if necessary. Once we have confirmed the problem, the solution will be offered within 24 to 48 hours.