Products

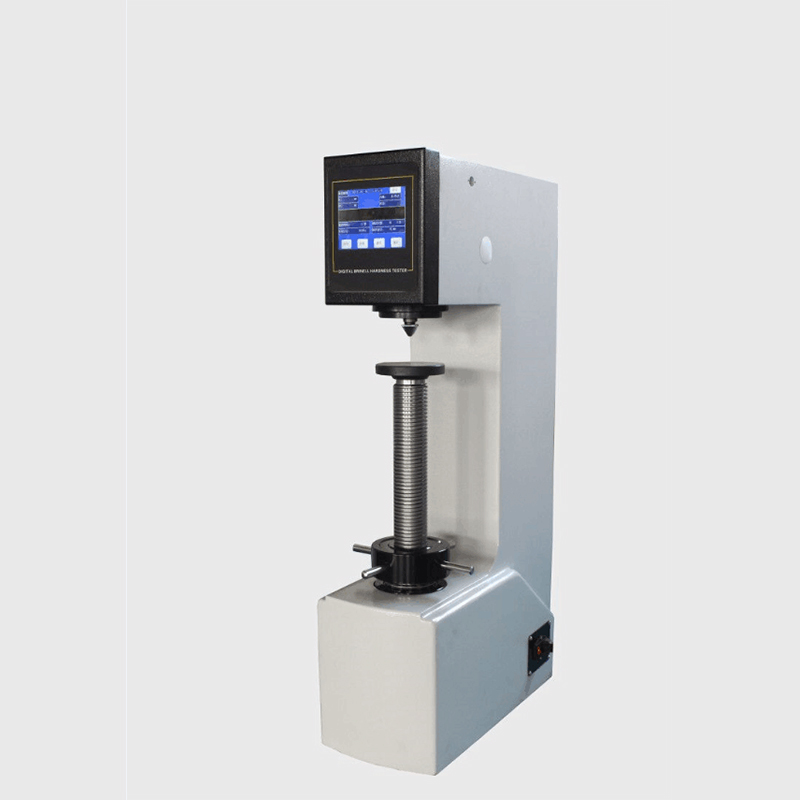

HBS-62.5(A) (automatic turret) digital display small load Brinell hardness tester

Adaptation

Determination of Brinell hardness of ferrous metals, non-ferrous metals and bearing alloy materials;

It has a wide range of applications, especially for Brinell hardness testing of soft metal materials and small parts.

Features

1. The body part of the product is formed at one time by the casting process, and has undergone a long-term aging treatment. Compared with the paneling process, the long-term use of the deformation is extremely small, and it can effectively adapt to various harsh environments;

2. Car baking paint, high-grade paint quality, strong scratch resistance, and still bright as new after many years of use;

3. The optical system designed by the senior optical engineer not only has a clear image, but also can be used as a simple microscope, with adjustable brightness, comfortable vision, and not easy to fatigue after long-term operation;

4. Equipped with an automatic turret, the operator can easily and freely switch the high and low magnification objective lenses to observe and measure the sample, avoiding the damage to the optical objective lens, indenter and test force system caused by human operation habits;

5. The high-resolution measurement and observation objective lens, combined with the high-definition digital measurement eyepiece with built-in length encoder, realizes one-key measurement of the indentation diameter, and gets rid of the errors and troubles of manual input during the reading process;

6. Optional CCD image processing system and video measurement device;

7. Configured with Bluetooth module, Bluetooth printer, and optional Bluetooth PC receiver to realize wireless printing and wireless data transmission;

8. Accuracy conforms to GB/T231.2, ISO 6506-2, ASTM E10.

Specifications

1. Measuring range: 5-650HBW

2 Test force:

9.807, 49.03, 98.07, 153.2, 294.2, 612.9N

(1, 5, 10, 15.625, 30, 62.5kgf)

3. Optical measurement system

Objective: 2.5×, 10×

Total magnification: 25×, 100×

Measuring range: 200μm

Graduation value: 0.025μm

4. Dimensions and power supply

Dimensions: 600*330*700mm

Maximum allowable height of the sample: 200mm

Distance from the center of the indenter to the machine wall: 130mm

Power supply: AC220V/50Hz;

Weight: 70Kg

Main accessories

Daping test platform: 1

Brinell Ball Indenter: Φ1, Φ2.5, 1 each

Xiaoping test platform: 1

Standard Brinell hardness block: 2

V-shaped test stand: 1

Printer: 1