Products

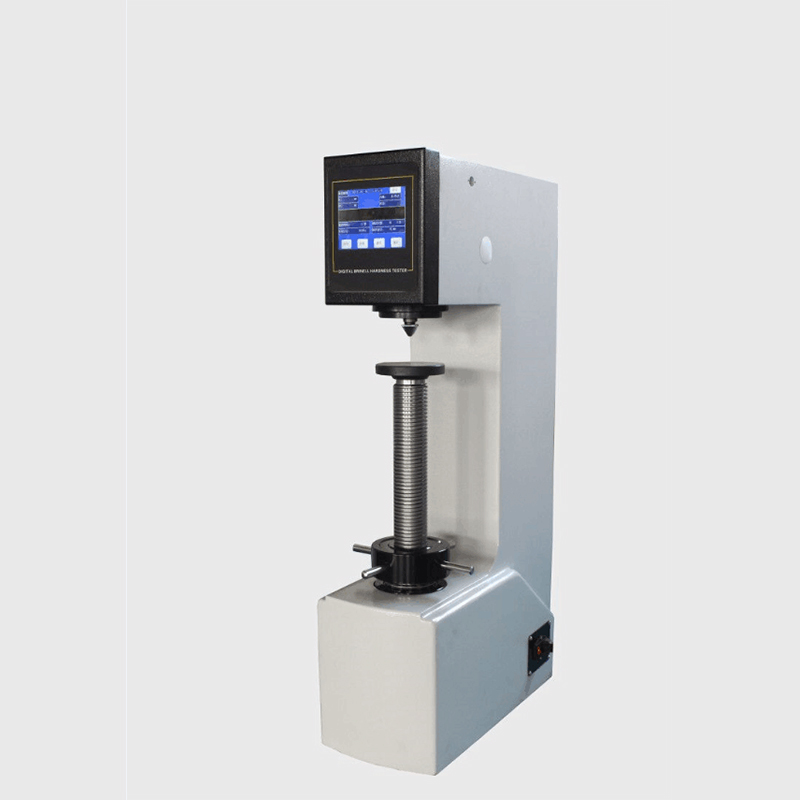

HBE-3000A Electronic Brinell Hardness Tester

Features

1. The body part of the product is formed at one time by the casting process, and has undergone a long-term aging treatment. Compared with the paneling process, the long-term use of the deformation is extremely small, and it can effectively adapt to various harsh environments;

2. Car baking paint, high-grade paint quality, strong scratch resistance, and still bright as new after many years of use;

3. Adopt electric loading and unloading test force, closed-loop feedback by pressure sensor with 5‰ precision, controlled by ARM32-bit single-chip microcomputer, and can automatically compensate the test force in the test;

4. Solid structure, good rigidity, accurate, reliable, durable, and high test efficiency;

5. Overload, over-position, automatic protection, electronic afterburner, no weight; automatic test process, no human operation error;

6. Equipped with high-performance stepping motor for automatic loading and unloading, the noise generated during the test is smaller;

7. Optional CCD image processing system and video measurement device;

8. Accuracy conforms to GB/T231.2, ISO6506-2 and American ASTM E10 standards.

Specifications

1. Measuring range: 5-650HBW;

2. Test force: 612.9, 980.7, 1225.9, 1838.8, 2415.8, 4903.5, 7355.3, 9807, 14710.5, 29421N (62.5, 100, 125, 187.5, 250, 500, 750, 1000, 1500, 3000kgf);

3. The maximum allowable height of the sample: 280mm;

4. Distance from the center of the indenter to the machine wall: 150mm;

5. Dimensions: 700*268*842mm;

6. Power supply: AC220V/50Hz

7. Weight: 210Kg.

Main accessories

Large flat workbench, small flat workbench, V-shaped workbench: 1 each;

Steel ball indenter: Φ2.5, Φ5, Φ10 each 1;

Steel ball: 1 each of Φ2.5, Φ5, Φ10;

Standard Brinell hardness block: 2