Products

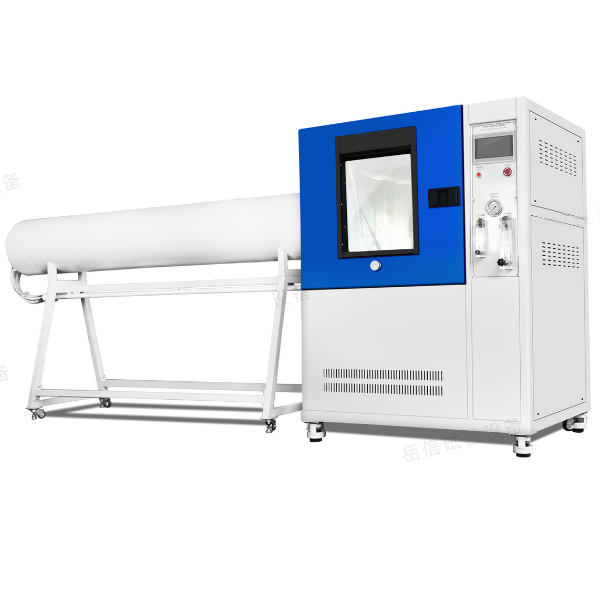

UP-6197 Sulfur Dioxide Gas Corrosion Test Chamber

Product Specifications:

It consists of a test chamber, a runner, a sample holder and a control panel. When conducting the test, the rubber sample is placed on the stand, and the test conditions such as load and speed are set on the control panel. The specimen holder is then rotated against the grinding wheel for a specified period of time. At the end of the test, the degree of wear is calculated by measuring the weight loss of the specimen or the depth of the wear track. Test results obtained from the Rubber Abrasion Resistance Akron Abrasion Tester are used to determine the abrasion resistance of rubber articles such as tires, conveyor belts, and shoe soles.

Applicable industries: rubber industry, shoe industry.

Determination of standard: GB/T1689-1998vulcanized rubber wear resistance machine(Akron)

Testing Condition

|

Attribute |

Value |

| Brand | UBY |

| Product Name | Sulfur Dioxide Salt Spray Test chamber |

| Power Supply | AC220V |

| Internal capacity | 270 L |

| Weight | About 200kg |

| External dimension | 2220×1230×1045 D×W×H (mm) |

| Internal dimension | 900×500×600 D×W×H (mm) |

| Material | SUS304 or customized |

| After-sales service | Yes |

Technical Specifications:

|

Model |

UP-6197 |

|

Power Supply Information |

|

|

Maximum watt |

2.5KW |

|

Specimen limitations |

|

|

Performance Index |

|

|

Meet standard |

GB2423.33-89, DIN 50188-1997, GB/T10587-2006, ASTM B117-07a, ISO 3231-1998, GB/T2423.33-2005, GB/T5170.8-2008 |

Note: Performance index above is under the condition of environment temperature is +25ºC, and R.H. is ≤85%, no test sample in the chamber.

Our service:

During the whole business process, we offer Consultative Selling service.

FAQ:

Moreover, If your machine doesn’t work, you can send us an e-mail or call us we will try our best to find the problem through our conversation or by video chat if necessary. Once we have confirmed the problem, the solution will be offered within 24 to 48 hours.