Products

UP-2001 Versatile Single Column Tensile Testing Machine

Design standards:

ASTM D903, GB/T2790/2791/2792, CNS11888, JIS K6854, PSTC7,GB/T 453,ASTM E4,ASTM D1876,ASTM D638,ASTM D412,ASTM F2256,EN1719,EN 1939,ISO 11339,ISO 36,EN 1465,ISO 13007,ISO 4587,ASTM C663,ASTM D1335,ASTM F88,ASTM D882 or ASTM D5034,ASTM F2458,EN 1465,ISO 2411,ISO 4587,ISO/TS 11405,ASTM D3330,FINAT.......

Main functions:

This machine is suitable for various textile, rubber, plastic, synthetic leather, tape, adhesive products, plastic film, composite materials, electronics, metal and other industries to do stretching, compression, bending, shearing, stripping (90 degrees and 180 degrees), tearing and other kinds of tests to determine the quality of products.

This machine is a simple tensile testing machine with simple structure and convenient operation.It adopts touch screen control system to control the rotation of frequency conversion motor, and then drives the t-type screw to drive the load sensor to rise and fall after the deceleration of the variable speed mechanical mechanism, so as to complete the tensile or compression test of samples.The force value is output by the sensor, the feedback display, the test displacement real-time display.Can achieve the value of fixed force, positioning and other tests.Can store the results of 10 test reference points, automatically calculate its average value, automatically grab the maximum value, the value of force at the time of fracture.

The thermal printer can automatically output test results.

Specification:

| Capacity | 5,10,20,50,100,200KG Optional |

| Test accuracy | ±1% |

| Display mode | Computer controlled |

| Unit change | Kg,lb,N |

| Data sampling frequency | 200times/sec |

| Resolution | Max load 1/±25000,no internal or external grading, and the overall resolution remains the same |

| Load cell | Basic configuration: tension and pressure sensors (maximum load) |

| Effective Test width | 150mm |

| Effective test height | 800mm |

| Test speed range | 50-300mm/min |

| Accuracy of displacement measurement | ±1% |

| Breakpoint ratio setting | 0~99%,Users can set the appropriate break down time according to different materials |

| Safety device | Up and down travel limit device |

| Overload protection | automatic shutdown over 10% of the maximum load, and machine overload, emergency shutdown device, up and down travel limit device. |

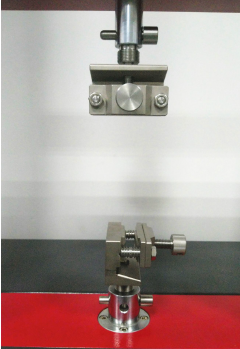

| Fixture | Tensile/compression each 1 set |

| Machine size | 500×400×1300mm |

| Machine weight | About 70 Kg |

Our service:

During the whole business process, we offer Consultative Selling service.

FAQ:

Moreover, If your machine doesn’t work, you can send us an e-mail or call us we will try our best to find the problem through our conversation or by video chat if necessary. Once we have confirmed the problem, the solution will be offered within 24 to 48 hours.