Products

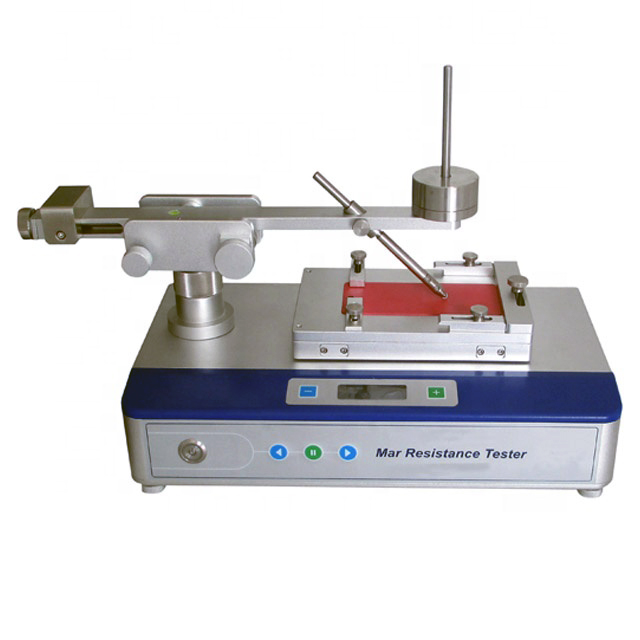

UP-6015 Friction Coefficient Scratch Resistance Tester

What is “Mar”

Mar resistance test for coatings is very similar with scratch resistance test, but this test uses arc(loop-shaped or ring-shaped)stylus to test the mar resistance of a single coating of a paint, varnish or related product,or the upper layer of a multi-coat system.

The product or system under test is applied at uniform thickness to flat panels of uniform surface texture. After drying/curing, the mar resistance is determined by pushing the panels beneath a curved (loop-shaped or ring-shaped)stylus which is mounted so that it presses down on the surface of the test panel at an angle of 45°. The load on the test panel is increased in steps until thecoating is marred.

This test has been found to be useful in comparing the mar resistance ofdifferent coatings. It is most useful in providing relative ratings for as eries of coated panels exhibiting significant differences in mar resistance.Kindly note this test does not specify a method using a pointed stylus, two of which are specified in ISO 1518-1 and ISO 1518-2, respectively. The choice between the three methods will depend on the particular practical problem.

Mar resistance Tester produced by Biuged confirms the newest international standard ISO 12137-2011, ASTM D 2197and ASTM D 5178. It can offer from 100g to5,000g load to test panel.

Characters

Working speed can be adjusted from 0 mm/s~10 mm/s

Double adjusting balance device to reduce the test error because of level.

Two stylus for optional

Moveable working table is convenient for operator do more tests at different areas in the same test panel.

Liftable balance arm can do mar test on the different thickness panels from 0mm~12mm

Main Technical Parameters

|

Motor Power |

60W |

| Weights | 1×100 gram, 2×200 gram, 1×500 gram, 2×1000 gram, 1×2000gram |

| Loop-shaped Stylus | Made of chromium-plated steel and shall be in the form of a rod of 1,6 mm diameter bent into a “U” shape with an outside radiusof(3.25±0.05)mm . With smooth surface and hardness is Rockwell HRC56 to HRC58 and its surface shall be smooth(roughness 0.05 μm). |

| Stylus moving speed | 0 mm/s~10 mm/s(step: 0.5mm/s) |

| Angle between stylus with test panels | 45° |

| Test panels Size | Less than 200mm×100mm(L×W),Thickness is less than 10mm |

| Power | 220VAC 50/60Hz |

| Overall Size | 430×250×375mm(L×W×H) |

| Weight | 15kg |

Our service:

During the whole business process, we offer Consultative Selling service.

FAQ:

Moreover, If your machine doesn’t work, you can send us an e-mail or call us we will try our best to find the problem through our conversation or by video chat if necessary. Once we have confirmed the problem, the solution will be offered within 24 to 48 hours.