Products

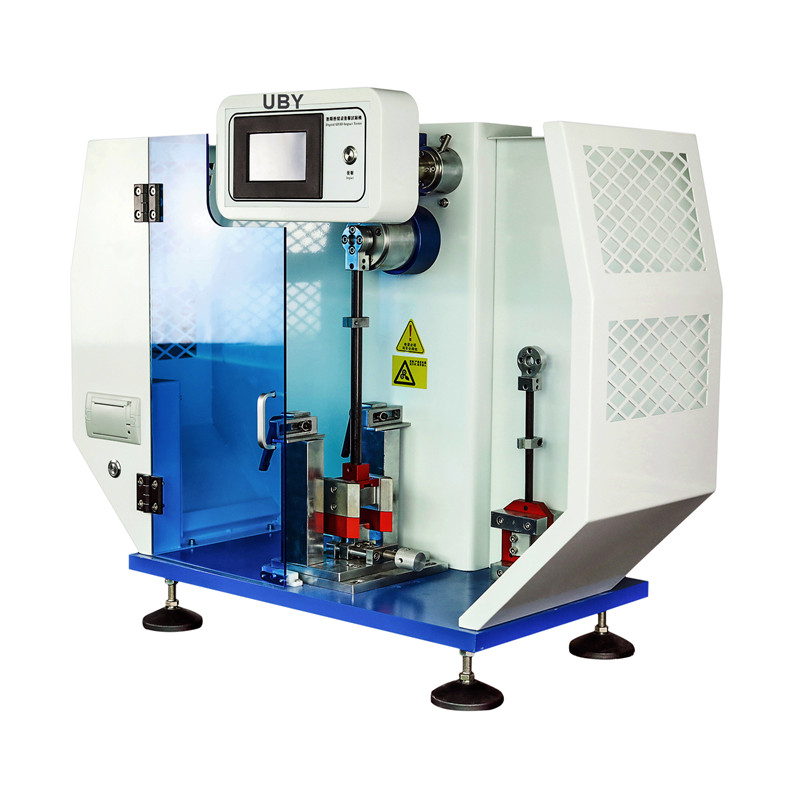

UP-2003 Two Column Versatile Tensile Testing Machine

Design standards:

GB16491-2008,HGT 3844-2008 QBT 11130-1991,GB 13022-1991,HGT 3849-2008,GB 6349-1986 GB/T 1040.2-2006 2411,ISO 4587,ISO/TS 11405,ISO 527,ASTM E4,BS 1610,DIN 51221,ISO 7500,EN 10002,ASTM D628,ASTM D638,ASTM D412

Use:

Suitable for aerospace, petrochemical industry, machinery manufacturing, metal materials and products, plastic,wire and cable,rubber, paper and plastic color printing packaging, adhesive tapes, bags handbags, textile fibers, textile bags, food,pharmaceutical and other industries.

To test the physical properties of the various materials and finished products, semi-finished products.choose a variety of fixture to do tensile, compressive, hold, hold pressure, bending, tear, peel, adhesion and shear test.It is an ideal testing and research equipment for factories, technical supervision departments, commodity inspection institutions, scientific research institutes and colleges and universities.

This machine is mainly used for testing the mechanical properties of metals such as tensile, compression, bending, etc.According to GB, JIS, ASTM, DIN and other standards can be automatically calculated tensile strength, yield strength, elongation, constant elongation stress, constant stress elongation, elastic modulus and other parameters.

Features:

1. The machine has completely changed the new material testing machine for the whole calculator operation, which was developed from the shortcomings of the conventional material testing machine, which is bulky, complex and complicated.

2. The structure adopts the steel plate and aluminum extruded plate with advanced baking paint, with high precision, low resistance, seamless precision screw and guiding column, which improves the load efficiency and structural rigidity.

3. The control system adopts the motor of the whole digital communication server to ensure that the transmission system is high in efficiency, stable in transmission, low in noise and accurate in speed.

4. Microcomputer system by commercial calculator as the main control machine, cooperate with the company's QCTech testing software, can complete all of the test parameters setting, working state control, data acquisition and processing analysis,result display and printing output;

5. Dedicated measurement and control system is specially designed for microcomputer electronic universal testing machine.It can stretch, compress, bend, shear, tear and peel off test.The data acquisition, preservation, processing and printing test results of PC and interface board are adopted.It can calculate the maximum force, yield force, average stripping force,maximum deformation, yield point, elastic modulus and other parameters;It can perform curvilinear processing, graphical graphical interface, flexible data processing, ms-access database support, making the system more powerful.

Parameters and specifications:

1. Software Technical Parameters:

Software operating system language: English,Chinesse

Force units: N, KN, Kgf, Lbf, length units: mm, cm, in can be freely converted

Control mode:

The computer software sets the speed, load rupture, running time and other control methods

Special manual operation box: convenient for calibration and positioning when loading and holding test pieces

Automatically determine material fracture, crushing, etc. And automatically stop, can set automatic return

Curve type:

Load-displacement, load-time, displacement-time.

Stress-strain, strain-time, stress-time.

The vertical and horizontal coordinates of the curve can be set arbitrarily.

Available test data:

Maximum strength, minimum strength, fracture value, upper and lower yield strength, tensile strength, compressive strength,elastic modulus, elongation, maximum value, minimum value, average value, etc.(customers need to select before ordering) with overload, overcurrent, overvoltage, undervoltage, overspeed, stroke and other multiple protection.

The data results are derived from the current standard crystal report format.

Specification:

| Capacity | kg | 2000 | 1000 | 500 | 200 | 100 |

| Accuracy | High precision | 0.5 level , ±0.5%, | ||||

| Load sensing | High precision tension and pressure transducer,(multiple sensors can be installed at the same time - optional) | |||||

| High resolution | 1/500000 | |||||

| Magnification | 24digit AD No period of zoom | |||||

| Unit choose | N, KN, Kgf, Lbf | |||||

| Test speed range | Servo : 0.1~500 mm/min can set | |||||

| Speed control accuracy | ±0.2% (0.5level ) | |||||

| Test effective width | 400 mm | |||||

| Test effective stroke | 700 mm | |||||

| Two column height | 1400 mm | |||||

| Overload setting protection function | When the set test force exceeds 10%, the system will automatically stop for protection | |||||

| Protection function of stroke setting | Protection for upper and lower limit position of stroke | |||||

| Motor | Servo motor | AC Servo motor & servo drive controller | ||||

| Power consumption | 0.5 kVA | |||||

| Power | 1ø, 220 VAC, 50/60 Hz | |||||

| Computer | Hardware | The supplied hardware specifications can be purchased from the original ACER brand or supplied by the customer | ||||

| Special software | Refer to the software version of the computer measurement system | |||||

| Volume | 65x55x220cm | |||||

| Weight | 200 kg | |||||

| Standard accessories | Tension fixture1pair, a group of tools, a manual, a warranty | |||||

| Optional | Extensometer | Elongation extensometer(gauge:25,50,75,100mm) | ||||

| Fixture | Can customer tensile/compression fixtures | |||||

Our service:

During the whole business process, we offer Consultative Selling service.

FAQ:

Moreover, If your machine doesn’t work, you can send us an e-mail or call us we will try our best to find the problem through our conversation or by video chat if necessary. Once we have confirmed the problem, the solution will be offered within 24 to 48 hours.