Products

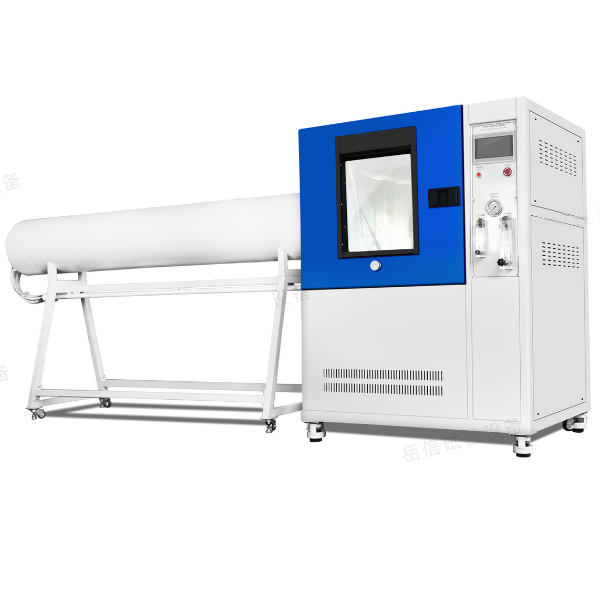

UP-6195 Temperature Humidity Control Accuracy Test Chamber

Product Overview:

Temperature Control:The temperature control range of the test chamber is from +20ºC to -40ºC, and it can achieve a temperature decrease rate of 1ºC per minute. This means that the chamber can quickly and accurately simulate extreme temperature conditions for testing purposes.

Humidity Control: The test chamber has a humidity fluctuation of ±1.0%RH, ensuring precise control of the humidity level. It can simulate different humidity environments to test the effects of humidity on products.

Heating Rate: The heating rate of the test chamber is from -70ºC up to +100ºC within 90 minutes. This means that the chamber can quickly reach high temperatures for testing purposes. It also has a temperature accuracy of ±0.5ºC, ensuring the reliability of test results.

Overall, the constant temperature and humidity test chamber is an essential tool for product testing, research, and development. Its advanced features and precise control make it suitable for a wide range of industries, including electronics, automotive, pharmaceuticals, and more.

Design Standard:

GB2423/T5170/10586/10592, IEC60068,GJB150,JIS C60068, ASTM D4714, CNS3625/12565/12566

Specification:

| Model | UP-6195-150L | UP-6195-225L | UP-6195-408L | UP-6195-800L | UP-6195-1000L |

| Temperature range | -70ºC ~ +150ºC | ||||

| Temperature fluctuation | ±0.5ºC | ||||

| Temperature uniformity | <=2.0ºC | ||||

| Heating rate | from -70ºC up to +100ºC within 90min (When unloaded, the ambient temperature is +25ºC) | ||||

| Temperature decrease rate | from +20ºC down to -70ºC within 90min (When unloaded, the ambient temperature is +25ºC) | ||||

| Humidity control range | 20%R.H~98%R.H | ||||

| Humidity deviation |

±3.0%RH(>75%RH) ±5.0%RH(≤75%RH) |

||||

| Humidity uniformity | ±3.0%RH(unloaded) | ||||

| Humidity fluctuation | ±1.0%RH | ||||

| Inner box size:WxHxD(mm) | 500x600x500 | 500x750x600 | 600×850×800 | 1000×1000×800 | 1000×1000×1000 |

| Outside box sizeWxHxD(mm) | 720×1500×1270 | 720×1650×1370 | 820×1750 ×1580 | 1220×1940 ×1620 | 1220×1940 ×1820 |

| Warm-box | Outer chamber material: high quality carbon steel plate, surface for electrostatic color spray treatment. The left side of the box is φ50mm diameter holeInner chamber material :SUS304# stainless steel plate.

Insulation material: hard polyurethane foam insulation layer + glass fiber. |

||||

| Door | For a single door, install a heating wire in the door frame to prevent condensation in the door frame at low temperature. | ||||

| Inspection window | The W 300×H 400mm observation window is installed on the door of the box, and multi-layer hollow electrothermal coated glass can effectively keep heat and prevent condensation. | ||||

| Lighting device | 1 LED lighting device, installed on the window. | ||||

| Sample holder | Stainless steel sample rack 2 layers, height adjustable, bearing weight 30kg/ layer. | ||||

| Refrigeration compressor | France Tecumseh fully closed compressor (2 sets) | ||||

| Coolants | Non-fluorine environmental refrigerant R404A, in line with environmental regulations, safe and non-toxic | ||||

| Condenser system | air-cooled | ||||

| Safety protection device | Heater anti-burning protection; Humidifier anti-burn protection; Heater overcurrent protection; Humidifier overcurrent protection; Circulating fan overcurrent overload protection; Compressor high pressure protection; Compressor overheat protection; Compressor overcurrent protection; Overvoltage underinverse-phase protection; Circuit breaker; Leakage protection; Humidifier low water level protection;Tank low water level warning. | ||||

| Power | AC220V;50Hz;5.5KW | AC380;V50Hz;7KW | AC380;V50Hz;9KW | AC380;V50Hz;11KW | AC380;V50Hz;13KW |

Our service:

During the whole business process, we offer Consultative Selling service.

FAQ:

Moreover, If your machine doesn’t work, you can send us an e-mail or call us we will try our best to find the problem through our conversation or by video chat if necessary. Once we have confirmed the problem, the solution will be offered within 24 to 48 hours.