Products

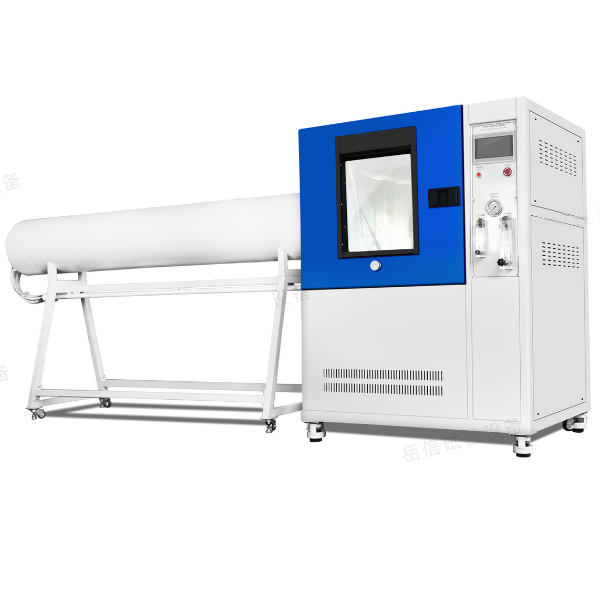

UP-6124 IEC62108 HAST High Pressure Accelerated Aging Test Chamber

Application:

Pressure accelerated aging tester is widely applied to the testing of sealing property for multi-layer circuit board, IC sealing package, LCD screen, LED, semi-conductor, magnetic materials, NdFeB, rare earths and magnet iron, in which the resistance to pressure and air tightness for above mentioned products can be tested out.

Product Description:

Hast High Pressure Accelerated Aging Test Chamber High Temperature High Pressure High Humidity Accelerated Aging Test Chamber is suitable for national defense, aerospace, automotive parts, electronic parts, plastics, magnet industry, pharmaceutical,circuit board, multi-layer circuit board, IC, LCD, magnet, lighting, lighting products and other products sealing performance testing, related products for accelerated life test, It is used in the design stage of the product to quickly expose the defects and weak links of the product. Test the product's aversion, air tightness.

Test Chamber Material:

| Temperature Range | RT-132ºC |

| Test Box Size | ∮350 mm x L500 mm), round test box |

| Overall Dimensions | 1150x 960 x 1700 mm (W * D * H) vertical |

| Inner Barrel Material | Stainless steel plate material (SUS# 304 5 mm) |

| Outer Barrel Material | Cold plate paint |

| Insulation Material | Rock wool and rigid polyurethane foam insulation |

| Steam Generator Heating Tube | Finned heat pipe-shaped seamless steel tube electric heater (platinum plating on the surface, anti-corrosion) |

Test chamber material:

Temperature range: RT-132ºC

Test box size: ∮350 mm x L500 mm), round test box

Overall dimensions: 1150x 960 x 1700 mm (W * D * H) vertical

Inner barrel material: stainless steel plate material (SUS# 304 5 mm)

Outer barrel material: cold plate paint

Insulation material: rock wool and rigid polyurethane foam insulation

Steam generator heating tube: finned heat pipe-shaped seamless steel tube electric heater (platinum plating on the surface, anti-corrosion)

Control system:

a. Use Japanese-made RKC microcomputer to control the saturated steam temperature (using PT-100 platinum temperature sensor).

b. The time controller adopts LED display.

c. Use pointer to display pressure gauge.

Mechanical structure:

a. Round inner box, stainless steel round test inner box structure, in line with industrial safety container standards.

b. The patented packing design makes the door and the box more closely integrated, which is completely different from the traditional extrusion type, which can extend the packing life.

c. Critical point LIMIT mode automatic safety protection, abnormal reason and fault indicator display.

Security protection:

a. Imported high temperature resistant sealed solenoid valve adopts double loop structure to ensure no pressure leakage.

b. The whole machine is equipped with over-pressure protection, over-temperature protection, one-key pressure relief, manual pressure relief multiple safety protection devices, to ensure the user's use and safety to the greatest extent.

c. Back pressure door lock device, the door of the test chamber cannot be opened when there is pressure inside the test chamber.

Other accessory accessories

1 set of test racks

Sample tray

Power supply system:

The fluctuation of the system power supply shall not exceed ±10

Power supply: single-phase 220V 20A 50/60Hz

Environment & Facilities:

Allowable working environment temperature 5ºC~30ºC

Experimental water: pure water or distilled water

Our service:

During the whole business process, we offer Consultative Selling service.

FAQ:

Moreover, If your machine doesn’t work, you can send us an e-mail or call us we will try our best to find the problem through our conversation or by video chat if necessary. Once we have confirmed the problem, the solution will be offered within 24 to 48 hours.