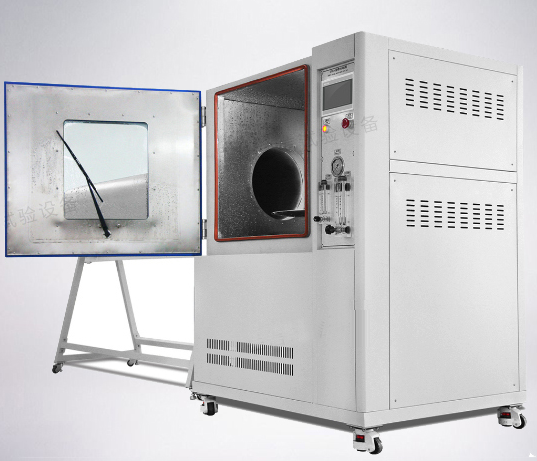

Firstly, it is necessary to understand the functions of the rain proof test box:

1. Its equipment can be used in workshops, laboratories and other places for IPX1-IPX6 waterproof level testing.

2. Box structure, recycled water, energy-saving and environmentally friendly, no need to build a dedicated waterproof laboratory, saving investment costs.

3. There is a transparent large window (made of tempered glass material) on the door, and LED lighting is installed inside the rain proof test box for easy observation of internal testing conditions.

4. Rotary table drive: using imported motors, the speed and angle can be set on the touch screen (adjustable), stepless adjustable within the standard range, and can automatically control the forward and reverse rotation (forward and reverse: suitable for product power testing to prevent winding).

5. The testing time can be set on the touch screen, with a setting range of 0-999min (adjustable).

Secondly, the purpose of its equipment:

According to standards such as IS020653, simulate a high-temperature and high-pressure steam cleaning process to conduct spray testing on automotive components. During testing, the samples are placed at four angles (0 °, 30 °, 60 °, 90 °) for high-temperature and high-pressure water jet testing. The device adopts an imported water pump, greatly ensuring the stability of the test. Mainly used for car wiring harnesses, car lights, car engines and other components.

Thirdly, the material description of the rain waterproof test box:

1. Shell: Processed from cold-rolled steel plate, with a surface sandblasted and powder sprayed, aesthetically pleasing and durable.

2. Inner box and turntable: all made of SUS304 # stainless steel plate to ensure long-term use without rusting.

3. Core control system: German "Jinzhong Mole" programmable controller, or well-known domestic brand "Dahua".

4. Electrical components: Imported brands such as LG and Omron are used (the wiring process fully meets the standard requirements). 5. High temperature and high pressure water pump: The equipment adopts original imported water pumps, which are resistant to high temperature and high pressure, can be used for a long time, and have stable performance.

Fourth, the execution standards of its equipment:

1. ISO16750-1-2006 Environmental Conditions and Tests for Electrical and Electronic Equipment of Road Vehicles (General Provisions); 2. ISO20653 Road vehicles - Protection levels (IP codes) - Electrical equipment - Protection against foreign objects, water, and contact; 3. GMW 3172 (2007) General requirements for the performance of vehicle environment, reliability, and rain resistance test chambers;

4. VW80106-2008 General test conditions for electrical and electronic components on automobiles;

5. QC/T 417.1 (2001) Car wire harness connectors Part 1

6. IEC60529 Electrical enclosure protection classification level (IP) code;

7. GB4208 shell protection level;

The above are all the things to know when purchasing rain proof test boxes.

Post time: Dec-04-2023