Lihlahisoa

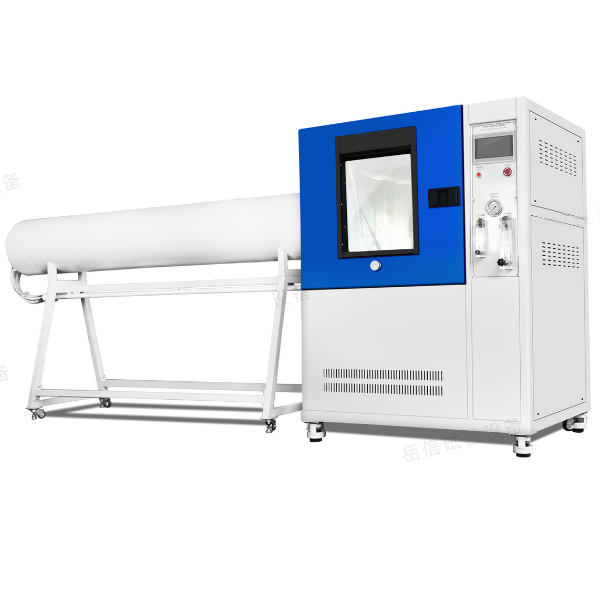

UP-2009 PC Electro-Hydraulic Servo Universal Testing Machine

Moamoheli

Moamoheli o na le cylinder tlas'a moeti, sebaka sa ho taka se fumaneha ka holim'a mainframe, 'me sebaka sa teko ea ho hatella le ho khumama se teng pakeng tsa sefate se seholo le tafole.

Sistimi ea phetiso

Enjene e phahamisang maballo e tlase ka mochini o fokotsang, mochini oa ho khanna ketane, bolo ea screw drive, ho fihlela ho otlolla, tokiso ea sebaka sa compression.

Sistimi ea hydraulic

Mokelikeli oa hydraulic ka tanka ea mafura o khannoa ke pompo e nang le khatello e phahameng ka har'a tsela ea oli ka koloing, e phalla ka valve ea ho hlahloba, mochine o motlakase oa khatello e phahameng, sehlopha sa khatello ea khatello ea khatello, valve ea servo, e kena ka silinda (fetola mochine o tloaelehileng ka lekhalo, kahoo ha e hlokomele ketsahalo ea ho lutla ha oli) K'homphieutha e romela letšoao la ho bula le ho laola servo valve, kahoo e laola ho phalla ka har'a cylinder, e hlokomela matla a kamehla a teko ea lebelo, ho falla ha lebelo le joalo joalo ka taolo.

Sistimi ea Taolo

Kenyelletso ea likarolo

1, tšehetso bakeng sa ho otlolla, ho hatella, ho itšeha, ho kobeha le liteko tse ling;

2, tšehetsa tlhahlobo e bulehileng ea ho hlophisa, hlophisa mehato e tloaelehileng le ho hlophisa, le ho ts'ehetsa tlhahlobo ea kantle ho naha, litekanyetso le lits'ebetso;

3, Ts'ehetso bakeng sa ho etsa tlhahlobo ea paramethara;

4, sebelisa foromo e bulehileng ea tlaleho ea EXCEL, tšehetso ea mofuta oa tlaleho ea tloaelo ea mosebelisi;

5, liphetho tsa tlhahlobo ea khatiso ea lipotso li bonolo ebile li bonolo ho ts'ehetsa ho hatisoa ha lisampole tse ngata, lintho tse hatisitsoeng tsa ho hlopha;

6, Lenaneo le tla le ts'ebetso e matla ea tlhahlobo ea liteko;

7, lenaneo la ts'ehetso ea boemo ba taolo ea maemo a holimo (mookameli, pilot) bolaoli ba taolo ea basebelisi;

Tlhaloso ea Software

1, Sebopeho se seholo sa sebopeho se na le mesebetsi e mengata, sebopeho se seholo sa lenaneo se kenyelletsa: sebaka sa menu ea tsamaiso, sebaka sa lisebelisoa, phanele ea ponts'o, phanele ea ponts'o ea lebelo, sebaka sa tlhahlobo ea liteko, sebaka sa tlhahlobo ea li-curve, sebaka sa ts'ebetso ea sephetho, sebaka sa tlhaiso-leseling ea liteko.

2, Curve rendering: Sistimi ea software e fana ka ponts'o e ntle ea liteko tsa curve. Joalo ka matla - phepelo ea phalliso, matla - curve ea deformation, khatello ea maikutlo - phepelo ea phalliso, khatello - curve ea deformation, matla - nako ea nako, deformation - nako ea nako.

3, Sehokelo sa tlhahlobo ea ts'ebetso ea data: ho latela litlhoko tsa mosebelisi e fumanoe ka bo eona, ReH, ReL, Fm, Rp0.2, Rt0.5, Rm, E le liphetho tse ling tsa liteko.

4, Sebopeho sa tlaleho ea liteko: sistimi ea ts'ebetso ea software e fana ka ts'ebetso e matla ea ts'ebetso ea tlaleho, bareki ba ka hatisa litlhoko tsa bona ho latela tlaleho ea tlhahlobo ea litlhoko tsa bona. Lintlha tsa liteko li ka bolokoa, tsa hatisoa le ho hlahlojoa.

5, sesebelisoa sa ts'ireletso ea ts'ireletso

Ha matla a teko a feta 3% ea matla a mangata a teko, tšireletso e feteletseng, ho koala motlakase oa pompo.

Ha piston e nyolohela sebakeng se ka holimo sa moeli, tšireletso ea stroke, mochine oa pompo o emisa.

Lintlha Tse Ka sehloohong

A) Setaele: Taolo ea Microcomputer, mofuta oa likholomo tse peli

B) Matla a phahameng a teko: 300KN;

C) qeto e fokolang ea matla a teko: 0.01N;

D) Lethathamo le nepahetseng la tekanyo: 4% -100% FS

E) ho nepahala ha matla a teko; molemo ho feta ± 1%

F) Qeto ea ho falla: 0.01mm;

G) Ho nepahala ha tekanyo ea ho falla: 0.01

H) Ho otlolla leeto: 600mm

I) Compression stroke: 600mm

J) Leqeba la piston: 150min

K) Ho nepahala ha taolo ea lebelo la ho falla: ± 1% (e tloaelehileng)

L) Boemo ba teko: 1 (e tloaelehileng) /0.5 boemo

M) Mehlahare ea mohlala e chitja e tšoara bophara: Φ6-Φ26mm

N) Mehlahare ea mohlala e bataletseng e tšoara botenya: 0-15mm

O) Boholo ba teko: 450 * 660 * 2520mm

P) Boholo ba mohlala o bataletseng oa clamping bophara: φ160mm

Q) Boholo ba poleiti ea khatello: φ160mm

R) Teko ea ho kokota Boholo bo bolelele pakeng tsa lintlha tse peli: 450 mm

S) bophara ba ho khumama: 120mm

T) Bophara ba ho bilika: Φ30 mm

H) Lebelo le phahameng la ho sisinyeha ha piston: 50mm / min

I) clamping mokhoa hydraulic clamping

J) Boholo bo boholo : 720 × 580 × 1950 limilimithara

k) Gauge cabinet boholo: 1000×700×1400mm

l) Phepelo ea matla: 220V, 50Hz

m) Boima ba teko: 2100kg

Tšebeletso ea rona:

Nakong ea ts'ebetso eohle ea khoebo, re fana ka litšebeletso tsa Consultative Selling.

LBH:

Ho feta moo, Haeba mochine oa hau o sa sebetse, o ka re romella e-mail kapa oa re letsetsa re tla leka ka hohle ho fumana bothata ka moqoqo oa rona kapa ka puisano ea video ha ho hlokahala. Ha re se re netefalitse bothata, tharollo e tla fanoa nakong ea lihora tse 24 ho isa ho tse 48.