Cov khoom

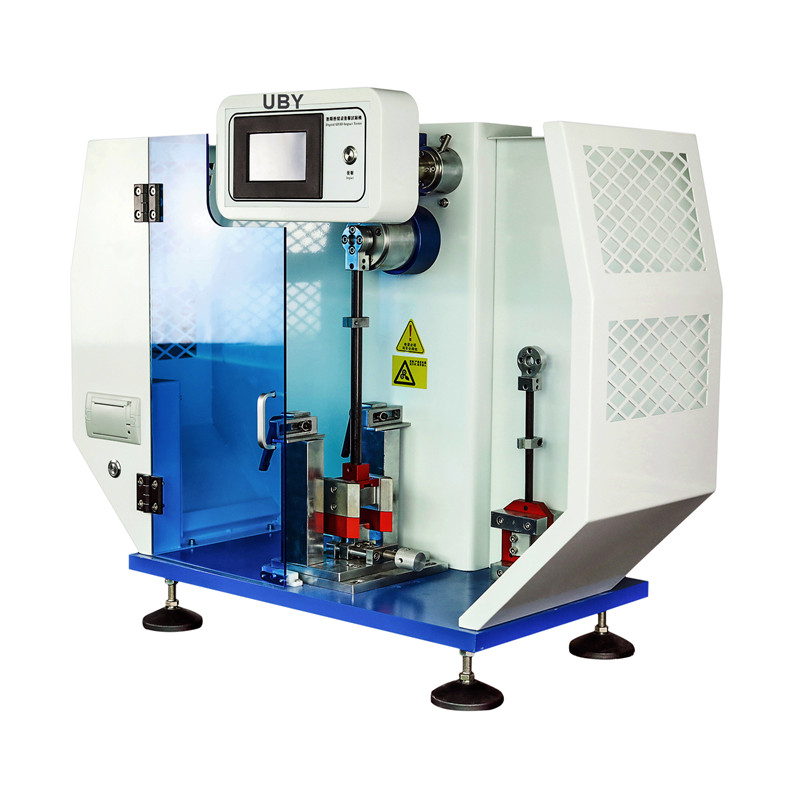

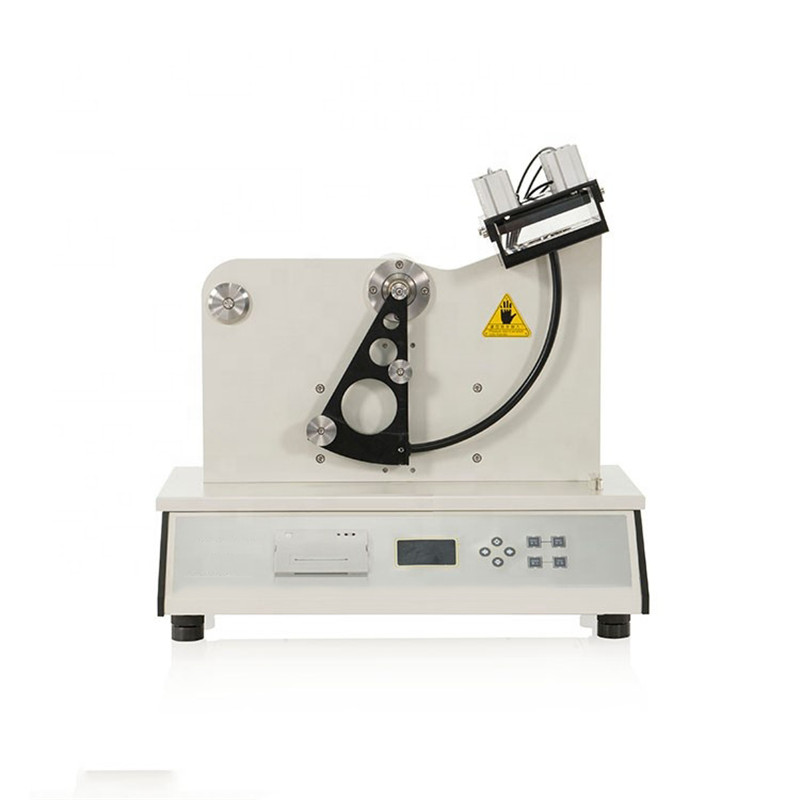

UP-2003 Textile Fabrics Tensile Strength Testing Tshuab

Cov Qauv:

ASTM D903, GB/T2790/2791/2792, CNS11888, JIS K6854, PSTC7, GB/T 453, ASTM E4, ASTM D1876, ASTM D638, ASTM D412, ASTM F2256, EN1719, EN 1939, ISO 11339, ISO 36, EN 1465, ISO 13007, ISO 4587, ASTM C663, ASTM D1335, ASTM F2458, EN 1465, ISO 2411, ISO 4587, ISO/TS 11405, ASTM D3330, FINAT thiab lwm yam.

Cov yam ntxwv ntawm cov khoom:

1. Lub cev muaj zog: Panasonic servo motor + Servo tsav tsheb + High precise ball ntsia hlau

2. Kev tswj hwm: a, kev tswj hwm lub khoos phis tawj; b, Rov qab mus rau keeb kwm tom qab qhov kev sim, c, khaws cov ntaub ntawv cia lossis los ntawm kev ua haujlwm phau ntawv

3. Kev xa cov ntaub ntawv: RS232

4. Kev daws teeb meem hloov chaw: 0.001 hli

5. Kev kho kom zoo dua ntawm daim duab qhia tuaj yeem ua rau daim duab pom tau zoo tshaj plaws thiab tuaj yeem siv cov duab hloov pauv hauv kev sim thiab muaj lub zog-ntev, lub sijhawm quab yuam, lub sijhawm ntev, kev ntxhov siab-kev ntxhov siab.

6. Nws tuaj yeem khaws cov txiaj ntsig tau tom qab kev sim tiav, thiab nws yog kev sau ntawv tes. Nws tuaj yeem tso saib lub zog siab tshaj plaws, lub zog tso zis, lub zog compressive, lub zog tensile, elongation, qhov siab tshaj plaws, qhov tsawg kawg nkaus thiab qhov nruab nrab ntawm daim tawv nqaij, thiab lwm yam.

7. Tus neeg siv tuaj yeem teeb tsa cov yam ntxwv ntawm cov khoom siv xws li ntev, dav, tuab, vojvoog, thaj chaw thiab lwm yam.

8. Cov lus: Lus Askiv, Suav

Kev Qhia Tshwj Xeeb:

| Khoom | Kev piav qhia |

| Lub Zog Siab Tshaj Plaws | 2000 kg (20KN) |

| Load cell | Lub teb chaws Yelemees hom load cell rau qhov tseeb siab |

| Kev tswj hwm | PC nrog lub qhov rais 7 system |

| Lub cev muaj zog | Panasonic servo motor w/ DC variable speed drive system, high-precision mechanical ball screw rod |

| Yuam kom nyeem ntawv | kgf, Ibf, N, KN, T thiab lwm yam |

| Stoke | 1200mm suav nrog lub teeb tsa |

| Kev daws teeb meem ntawm tes thauj khoom | 1/250,000 |

| Kev Ntsuas Qhov Tseeb | ≤0.5% |

| Kev sim ceev | 0.1 ~ 500 hli / feeb (kho tau los ntawm PC) |

| Qhov dav ntawm kev sim | ≤400 hli |

| Cov duab nkhaus | Kev thauj khoom- elongation, Elongation-time, Time-elongation, Stress-strain |

| Cov ntaub ntawv tso saib | Lub zog siab tshaj plaws, qhov ceev, cov ntaub ntawv qauv, lub zog (Kpa, Mpa, N/mm, N/mm2) thiab lwm yam ... |

| Cov yam ntxwv kev nyab xeeb | E-Stop Kev tiv thaiv overload Cov kev hloov pauv sab saud thiab qis dua Load sensor nrog automatic retreat |

Cov Haujlwm:

1. Kev hloov pauv raws li qhov hnyav uas tau teev tseg: Kev hloov pauv sim raws li qhov hnyav uas tau teev tseg ntawm cov qauv kuaj

2. Kev thauj khoom raws li kev hloov pauv txhais: Kev thauj khoom sim raws li kev hloov pauv txhais ntawm cov qauv kuaj

3. Software tuaj yeem tshaj tawm cov ntaub ntawv nrog cov txiaj ntsig rau qhov siab tshaj plaws. lub zog, elongation, tensile lub zog, tev tawv lub zog, kua muag lub zog, compression lub zog, thiab lwm yam.

4. Lub tshuab no tuaj yeem ua ntau yam kev sim raws li tus neeg siv khoom xav tau xws li kev sim tev tawv, kev sim kua muag, kev sim nias, kev sim khoov nrog cov clamps sib txawv.

Peb qhov kev pabcuam:

Thaum lub sijhawm ua lag luam tag nrho, peb muab kev pabcuam muag khoom sab laj.

Cov Lus Nug Feem Ntau:

Ntxiv mus, Yog tias koj lub tshuab tsis ua haujlwm, koj tuaj yeem xa email rau peb lossis hu rau peb peb yuav sim peb qhov zoo tshaj plaws los nrhiav qhov teeb meem los ntawm peb qhov kev sib tham lossis los ntawm kev sib tham video yog tias tsim nyog. Thaum peb tau lees paub qhov teeb meem, kev daws teeb meem yuav muab rau hauv 24 txog 48 teev.